雄安新区“智慧党建”

雄安新区“智慧党建”

广州番禺“智慧党建”

广州番禺“智慧党建”

党员教育平台

党员教育平台

西藏那曲色尼先锋“智慧党建”

西藏那曲色尼先锋“智慧党建”

山西太原铁路局“智慧党建”

山西太原铁路局“智慧党建”

贵州磷化“智慧党建”

贵州磷化“智慧党建”

烟草“智慧党建”

烟草“智慧党建”

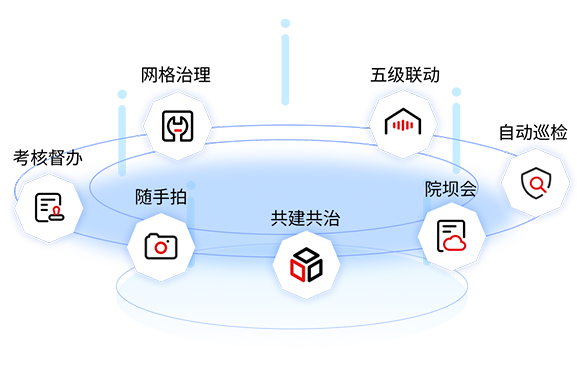

张家口万全区村域综合治理平台

张家口万全区村域综合治理平台

欧博电竞(科技)股份有限公司(股票代码:870543)是深耕聚焦于数字乡村、基层治理和智慧党建领域的国家级高新技术企业和省级“专精特新”中小企业。2012年公司创立,2018年引入战略投资者南天信息(股票代码:000948),完成A轮融资,是云南省工业投资控股集团旗下混改企业。

自成立以来,红岭云科技用理论研究夯实业务深度、用数字技术创新业务变革、用数字场景赋能党建引领,秉持“创新、创业、创未来”的核心价值观,为百年政党和亿万用户提供最具价值、最具创新的智慧化、数字化服务。

2020年全面启动“红色百年”战略,进行全国化市场拓展,以雄安、西南双总部进行运营管理,业务范围涵盖全国10余个省市、服务全国300余万用户、惠及全国4000余万群众,实现了行业领域的全国引领。

目前已获得了近200项软件著作权,拥有涉密信息系统软件开发集成资质、CMMI三级资质,ITSS技术运维资质、ISO9001、ISO14001、ISO27001等核心软实力,入选“雄安新区智能城市创新联合会”,担任“雄安科企联”常务理事单位;荣获中国“社会治理创新突出贡献品牌”企业、中国“软件和信息服务业最具影响力”行业品牌、中国数交会“最具创新精神”企业奖、2021年度云南省软件及信息技术服务行业十强等殊荣。